Menu

One such way is through our design-fabrication department. We work closely with design professions on plumbing, HVAC, site utility systems, and even process piping to meet building and budget requirements of our clients.

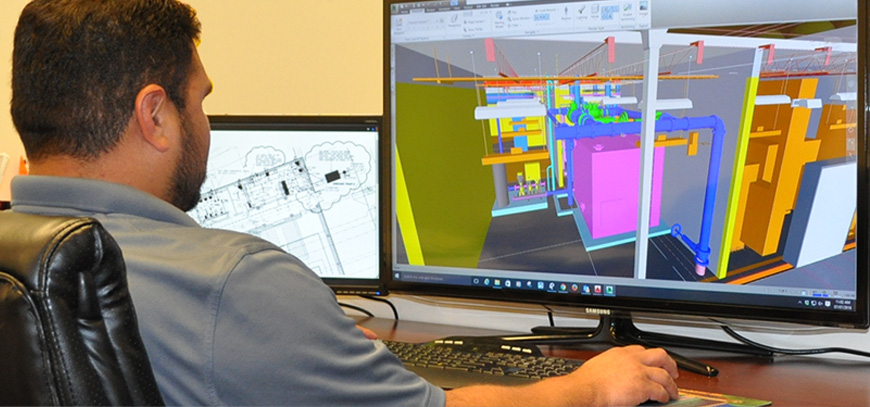

Once a project has been designed, we run the complete design package through a pre-fabrication process. We first determine which parts of a project are best suited for pre-fabrication. Our designers then utilize the latest advanced technologies of AutoCAD as well as other third-party design software to generate three-dimensional fabrication drawings for use in our fabrication shop.

This process also integrates seamlessly with Building Information Management (BIM) systems in conjunction with other trades.

Our draftsmen work under the direct supervision of an experienced management team to help ensure quality control.

After a system has been pre-fabricated, it is then prepared for shipping to the job site. Pre-fabrication allows us to maintain tighter quality control, increase productivity, and reduce exposure on the job site.

Raven Mechanical LP Copyright ©, 2021. Privacy Policy

Design and Powered: Nazca Tech & Consulting